Mechanical Ventilation System are essential for ensuring proper airflow and maintaining indoor air quality in modern buildings. These systems use mechanical components, such as fans and ducts, to supply fresh air and expel stale or polluted air, creating a healthier environment. Unlike natural ventilation, which relies on wind and building openings, mechanical systems provide consistent performance regardless of external conditions.

When planning to install a system, it is important to consider the specific requirements of the building, including its size, layout, and intended use. The type of system chosen—whether exhaust, supply, balanced, or heat-recovery—should match the ventilation demands of the space.

Furthermore, these systems are designed to accommodate various filters to capture pollutants, making them suitable for homes, offices, or industrial settings. With the right design and installation, these systems ensure efficient and reliable ventilation tailored to specific environments.

Types of Mechanical Ventilations Systems

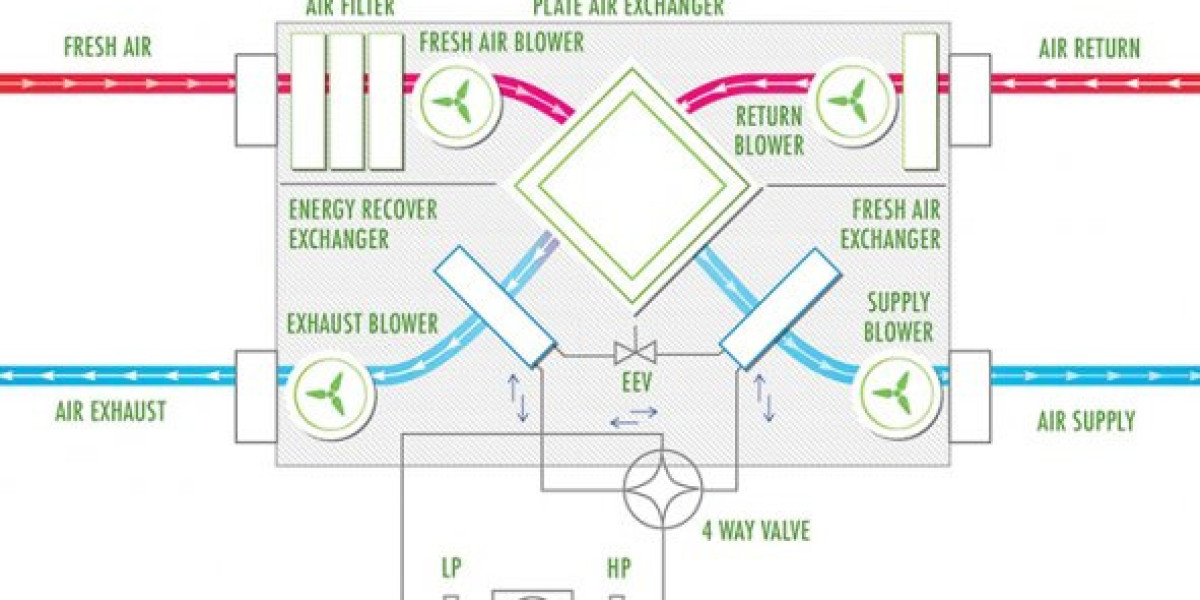

Mechanical Ventilations Systems are available in various types, each tailored to specific ventilation needs. Exhaust systems focus on removing indoor air, effectively expelling odours, humidity, and pollutants. Supply systems, on the other hand, deliver fresh outdoor air into the building, often passing it through filters to ensure cleanliness.

Balanced systems combine exhaust and supply functionalities, maintaining equilibrium between incoming and outgoing air volumes. Heat-recovery ventilation systems, a highly efficient option, utilise heat exchangers to transfer warmth from outgoing air to incoming air, reducing energy usage.

Specialised Systems for Enhanced Performance

Some advanced systems are designed for specific purposes, such as positive input ventilation, which prevents condensation, or demand-controlled ventilation, which adjusts airflow based on occupancy or air quality. Selecting the appropriate system requires careful consideration of building requirements, energy efficiency, and air quality demands.

Components of a Mechanical Ventilations System

A Mechanical Ventilations System operates effectively through the integration of several essential components. Fans form the backbone, ensuring consistent air movement throughout the system. Ductwork serves as a network of passageways, designed to transport air to and from various parts of the building. Filters are installed to capture dust, allergens, and other airborne particles, contributing to improved air quality.

Designing a Mechanical Ventilations System for Efficiency

When designing an efficient Mechanical Ventilations System, begin by assessing the building's specific ventilation requirements, considering factors such as occupancy levels, room usage, and potential sources of pollutants. Accurately calculate the airflow needed to maintain proper indoor air quality. Select appropriately sized equipment, ensuring fans, ducts, and filters match the building’s layout and ventilation needs. Plan the ductwork carefully, minimising bends and ensuring a well-sealed system to reduce pressure losses and energy waste.

Installation Process of a Mechanical Ventilations System

The installation of a Mechanical Ventilations System requires meticulous attention to detail to ensure optimal functionality. Begin by thoroughly reviewing the design plans, verifying that all components align with the building layout and ventilation requirements. Mark the precise locations for fans, ducts, and other equipment to ensure efficient airflow. Install ductwork first, taking care to secure it firmly to prevent leaks and vibrations. Ensure ducts are properly insulated to minimise energy loss and reduce noise. Position the fans in designated areas, connecting them to the ducts with suitable fixings and sealing any joints to maintain system integrity. Fit the filters in accessible locations for easy maintenance and verify that they meet the required specifications. Next, integrate any control systems, such as thermostats or occupancy sensors, as outlined in the system design. Conduct thorough electrical wiring and test all connections to confirm safety and reliability. Before operation, inspect the entire system for potential issues, ensuring everything is securely in place and ready for use.

Maintenance and Troubleshooting of Mechanical Ventilations Systems

Proper maintenance of a Mechanical Ventilations System involves several key steps to ensure optimal performance and longevity. Begin by inspecting the filters regularly, as clogged or dirty filters can impede airflow and reduce efficiency. Replace or clean them as per the manufacturer’s guidelines, typically every three to six months. Examine the ductwork for any visible signs of damage, leaks, or blockages, as these can lead to uneven airflow or energy loss.

Addressing Common Operational Issues

When troubleshooting, check for unusual noises from the fans, which may indicate loose components or motor issues. If airflow seems reduced, verify that the dampers are functioning correctly and inspect the fans for obstructions or wear. For systems equipped with electronic controls, ensure that sensors and connections are secure and calibrated. If electrical faults occur, confirm that all wiring is intact and adhere to safety protocols when addressing these issues. Regularly monitor airflow rates and ensure that all moving parts are adequately lubricated.

Benefits of Using Mechanical Ventilations Systems

1. Improves Indoor Air Quality

Mechanical ventilations systems continuously remove stale air and bring in fresh, filtered air, reducing indoor pollutants, allergens, and humidity levels.

2. Enhances Energy Efficiency

Modern systems are designed to recover heat from outgoing air, lowering energy costs while maintaining a comfortable indoor environment.

3. Provides Consistent Airflow

Unlike natural ventilation, mechanical systems deliver controlled and balanced airflow throughout the building, ensuring comfort in every room.

4. Supports Health and Well-Being

By reducing mold growth, allergens, and airborne contaminants, these systems promote healthier living and working spaces.

Enhanced Energy Efficiency and Health Benefits

Certain models, such as heat-recovery systems, are designed to recover and reuse heat, lowering energy consumption and reducing heating costs. This not only provides financial savings but also supports environmentally responsible practices. Additionally, improved air quality has been linked to better overall health, reducing respiratory issues and promoting wellbeing for occupants.

Advanced filtration options can further enhance air purity, making these systems ideal for individuals with allergies or sensitivities. By providing consistent and controlled ventilation, Mechanical Ventilations Systems ensure a safer and more pleasant indoor atmosphere year-round.

Challenges in Implementing Mechanical Ventilations Systems

Implementing Mechanical Ventilations Systems can involve various challenges that require careful attention and planning. One significant hurdle is ensuring proper integration with the existing building infrastructure, particularly in older properties with limited space or outdated layouts. Precise calculations are required to determine airflow rates and equipment sizing, as errors can lead to inefficiency or system failure.

Managing Costs and Energy Efficiency

Recent technological advancements have transformed the functionality and efficiency of Mechanical Ventilations Systems, addressing modern ventilation demands. One key development is the incorporation of smart sensors, which monitor air quality and automatically adjust airflow to maintain optimal conditions.

These sensors can detect humidity, carbon dioxide levels, and airborne particles, enabling precise system control. Another innovation is the integration of energy-efficient motors, which significantly reduce energy consumption while maintaining performance.

Advanced filtration technologies have also emerged, such as high-efficiency particulate air (HEPA) filters and activated carbon filters, enhancing pollutant removal capabilities. Additionally, the adoption of modular system designs allows for easier installation, customisation, and maintenance. Remote monitoring and control through mobile apps and building management systems further improve convenience, allowing users to optimise ventilation settings in real-time. These advancements collectively enhance both user experience and system effectiveness.

Environmental Impact of Mechanical Ventilations Systems

Mechanical Ventilations Systems, while enhancing indoor air quality and comfort, can contribute to energy consumption due to the operation of fans and other components. To mitigate this, prioritise the selection of systems that feature energy-efficient motors and components, which reduce electricity usage without compromising performance. Incorporating renewable energy sources, such as solar or wind power, can further offset the environmental footprint of these systems.

1. Energy Consumption

Mechanical ventilation requires electricity to operate fans and systems, which can increase overall energy demand if not designed efficiently.

2. Carbon Emissions

When powered by non-renewable energy sources, ventilation systems contribute to greenhouse gas emissions and climate change.

3. Resource Use in Manufacturing

The production of ventilation equipment involves raw materials, energy, and manufacturing processes that impact the environment.

4. Waste and End-of-Life Disposal

Improper disposal of old ventilation units can contribute to electronic and metal waste, affecting landfills and recycling systems.

5. Potential for Sustainable Integration

When combined with renewable energy and energy recovery technologies, modern systems can reduce environmental impact and support sustainable building practices.

Regulations and Standards for Mechanical Ventilations Systems

To ensure the safe and efficient operation of Mechanical Ventilations Systems, adherence to relevant regulations and standards is paramount. Building codes typically outline ventilation requirements, including minimum airflow rates, to maintain adequate indoor air quality.

Additionally, energy efficiency standards, such as those set by the Energy Performance of Buildings Directive (EPBD) in the UK, emphasise the need for systems that minimise energy consumption. Compliance with standards such as BS EN 13141, which governs performance testing of components, ensures reliable and effective system design.

Health and Safety Requirements

Mechanical Ventilations Systems must meet health and safety standards to protect occupants. For example, filters and ductwork should be designed to prevent the spread of airborne contaminants, while fan noise levels should comply with acceptable limits to maintain a comfortable environment. Installations in commercial or industrial buildings may also require additional certifications, such as compliance with Control of Substances Hazardous to Health (COSHH) regulations. Working with qualified professionals ensures compliance with these regulations.

Choosing the Right Mechanical Ventilations System for Your Needs

To choose the right Mechanical Ventilations System, begin by evaluating the property’s specific requirements, including its size, design, and intended usage. Calculate the necessary airflow to ensure adequate ventilation without overburdening the system. Consider the building’s insulation and identify areas prone to moisture or poor air circulation.

For residential spaces, a balanced or heat-recovery system may be suitable, offering energy efficiency and consistent air quality. In commercial or industrial environments, demand-controlled or exhaust systems could better address varying occupancy levels and pollutant loads. Factor in energy consumption, noise levels, and maintenance needs when selecting equipment.

Ensure the chosen system complies with relevant regulations and standards for safety and performance. Seek guidance from experienced professionals who can assess site-specific conditions and recommend the most efficient and cost-effective solution tailored to your needs.

Future Prospects of Mechanical Ventilations Systems

As the demand for energy-efficient and environmentally sustainable solutions grows, the future of Mechanical Ventilations Systems is set to feature significant advancements. Enhanced energy recovery technologies are being developed, enabling even greater reductions in energy consumption by optimising heat and moisture transfer processes.

The integration of artificial intelligence and machine learning is expected to revolutionise system functionality, allowing real-time adjustments based on occupancy patterns, air quality data, and weather conditions. Innovations in compact and modular designs will provide increased flexibility, catering to smaller spaces and facilitating easier retrofitting in older buildings.

Moreover, the inclusion of advanced sensors and Internet of Things (IoT) connectivity will enable seamless monitoring and remote management, offering improved efficiency and user convenience. These developments align with global sustainability goals and aim to meet evolving regulatory requirements, ensuring Mechanical Ventilations Systems remain integral to modern building design.

Conclusion

Mechanical Ventilation Systems are integral to maintaining indoor air quality, comfort, and energy efficiency across various settings. Proper planning, design, and installation ensure these systems meet the unique requirements of different buildings, from residential properties to industrial facilities. Selecting appropriate components, such as fans, ductwork, and filters, is crucial to achieving reliable performance and effective air circulation. Regular maintenance, including filter replacements and system inspections, helps to sustain efficiency while addressing potential operational issues promptly. Advances in technology, such as energy-efficient motors, smart controls, and enhanced filtration options, continue to improve system capabilities, offering tailored solutions to evolving ventilation needs. Complying with regulations and standards further guarantees safe and efficient operation. By integrating sustainable practices, such as heat-recovery systems or renewable energy, Mechanical Ventilations Systems contribute to environmentally responsible building design while prioritising occupant health and comfort.

6 FAQS

1. What are the main components of a Mechanical Ventilations System?

- Key components include fans for air movement, ductwork for air distribution, filters to remove pollutants, and dampers to regulate airflow.

2. How often should filters be replaced or cleaned?

- Filters should typically be cleaned or replaced every three to six months, depending on usage and manufacturer recommendations.

3. Can Mechanical Ventilation Systems reduce energy costs?

- Yes Mechanical Ventilation Systemwith energy recovery features and efficient designs can significantly reduce energy consumption.

4. What is the difference between supply and exhaust ventilation?

- Supply systems bring in fresh air, while exhaust systems remove stale indoor air.

5. How do smart controls improve system performance?

- They adjust airflow based on real-time data, ensuring efficiency.

6. Are these systems suitable for all building types?

- Yes, with appropriate design, they can be customised for residential, commercial, and industrial settings.

Related Business Listings |