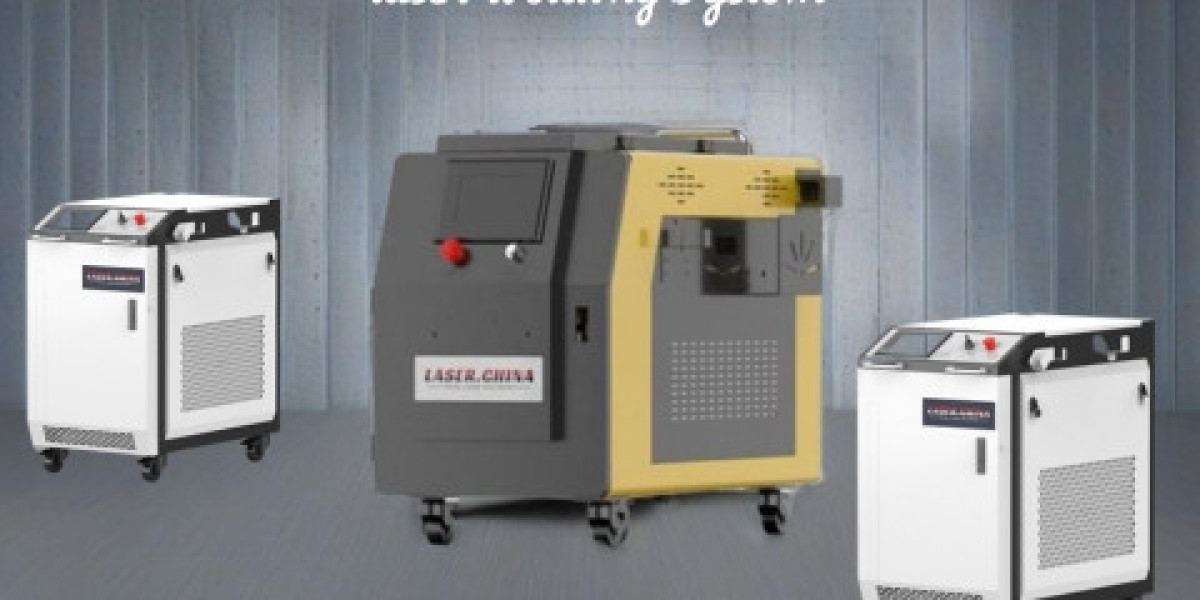

Laser welding systems have become indispensable tools across numerous industries—from automotive and aerospace to medical and consumer electronics. At the forefront of this technological evolution is LaserChina, a global leader in delivering precision-focused, high-efficiency laser welding solutions. In this comprehensive guide, we explore how LaserChina's systems redefine industrial welding through innovation, speed, and control.

What Is a Laser Welding System?

A laser welding system utilizes concentrated beams of light to melt and fuse materials at high speed and precision. It offers significant advantages over traditional methods:

High welding speed

Minimal thermal distortion

Precision for micro components

Automation compatibility

LaserChina’s systems are engineered to perform in demanding environments, offering top-tier power stability and control, ideal for both deep penetration and fine welding applications.

Why Choose LaserChina's Laser Welding Technology?

LaserChina has invested decades in laser technology innovation. Their systems integrate:

Fiber and CO₂ laser options

Modular configurations

Advanced control interfaces

Real-time monitoring for QC

Their R&D-backed systems meet international standards (CE, ISO) and are developed with precision-engineered optics and AI-driven software—perfect for industries needing tight tolerances and repeatability.

Key Benefits of LaserChina’s Laser Welding Systems

| Feature | Benefit |

|---|---|

| High Beam Quality | Ensures narrow, deep welds with minimal spatter |

| Customizable Configurations | Tailored to meet diverse industrial needs |

| 3D Motion Control Systems | Ideal for complex geometries |

| Energy Efficiency | Low operating costs with high laser efficiency |

| Compact & Scalable Design | Easy integration into new or existing production lines |

Applications Across Industries

LaserChina’s laser welding systems are widely used in:

Automotive: Battery packs, car frames, sensors

Electronics: Circuit boards, microconnectors

Aerospace: Turbine blades, structural components

Medical Devices: Surgical instruments, implants

Jewelry & Luxury Goods: Precision seams on fine metals

Laser Welding Types Supported by LaserChina

LaserChina supports multiple welding techniques depending on the application:

Conduction Welding – For thin materials requiring fine control

Deep Penetration Welding – For thick metals and structural components

Hybrid Welding – Laser + arc for strong, ductile joints

Each system is built with compatibility for robotic arms and CNC platforms, ensuring flexibility and scalability in smart manufacturing environments.

FAQs: LaserChina Laser Welding Systems

Q1: What materials can LaserChina's laser welders handle?

A: Stainless steel, aluminum, titanium, copper, and even dissimilar metals.

Q2: Is laser welding safe for mass production environments?

A: Yes. LaserChina systems come equipped with safety enclosures, interlocks, and remote diagnostics.

Q3: How does laser welding compare to traditional TIG/MIG?

A: Laser welding offers higher speed, greater precision, and lower heat input, resulting in minimal warping.

Q4: Can these systems be automated?

A: Absolutely. LaserChina designs are compatible with PLCs, robotics, and smart factory protocols (Industry 4.0).

Expert Insights: Why Manufacturers Trust LaserChina

25+ years of laser system development

Global installations in over 80 countries

Dedicated training and customer service teams

Real-world use cases from Tier 1 OEMs

LaserChina collaborates closely with manufacturing engineers to deliver custom-built solutions that optimize cycle times and maintain superior weld quality.

Performance Metrics That Matter

Laser Power Range: 500W to 3000W+

Repeatability Accuracy: ±0.01 mm

Max Welding Speed: Up to 10 m/min

Focus Spot Diameter: ≤0.1 mm

These numbers translate into unmatched precision and consistency for manufacturers aiming to scale without sacrificing quality.

Why LaserChina Is a Trusted Partner

LaserChina offers more than just equipment—they deliver:

On-site installation and training

24/7 remote support and diagnostics

Lifetime technical consultation

Spare parts and maintenance kits stocked globally

With a commitment to long-term partnerships, LaserChina empowers businesses to grow confidently with reliable, scalable laser welding solutions.

Final Thought

For companies navigating the fast-paced world of modern manufacturing, LaserChina's laser welding system provide the durability, precision, and scalability needed to remain competitive. With proven results across diverse sectors, LaserChina continues to set the benchmark in laser welding technology.