Laser cleaning machines have become an essential tool across various industries, from automotive and aerospace to restoration and manufacturing. With increasing demand for eco-friendly, non-abrasive, and efficient surface preparation methods, laser cleaners offer a cutting-edge alternative to sandblasting and chemical cleaning. But the most frequent question asked is: What is the laser cleaning machine price in 2025? Here's everything you need to know.

Laser Cleaning Machine Price in 2025: Cost Breakdown Table

| Type of Laser Cleaner | Power Output | Common Applications | Estimated Price Range (USD) |

|---|---|---|---|

| Entry-Level Handheld Unit | 50W–100W | Light rust, paint removal | $3,000 – $8,000 |

| Mid-Range Industrial Unit | 200W–500W | Factory equipment, mold cleaning | $10,000 – $40,000 |

| High-Power Robotic System | 1000W+ | Shipyards, aerospace, large facilities | $50,000 – $150,000+ |

What Affects the Price of a Laser Cleaning Machine?

Laser cleaning equipment isn’t one-size-fits-all. Several key factors impact pricing:

Wattage & Power Output: Higher wattage means faster and deeper cleaning but comes with a higher price.

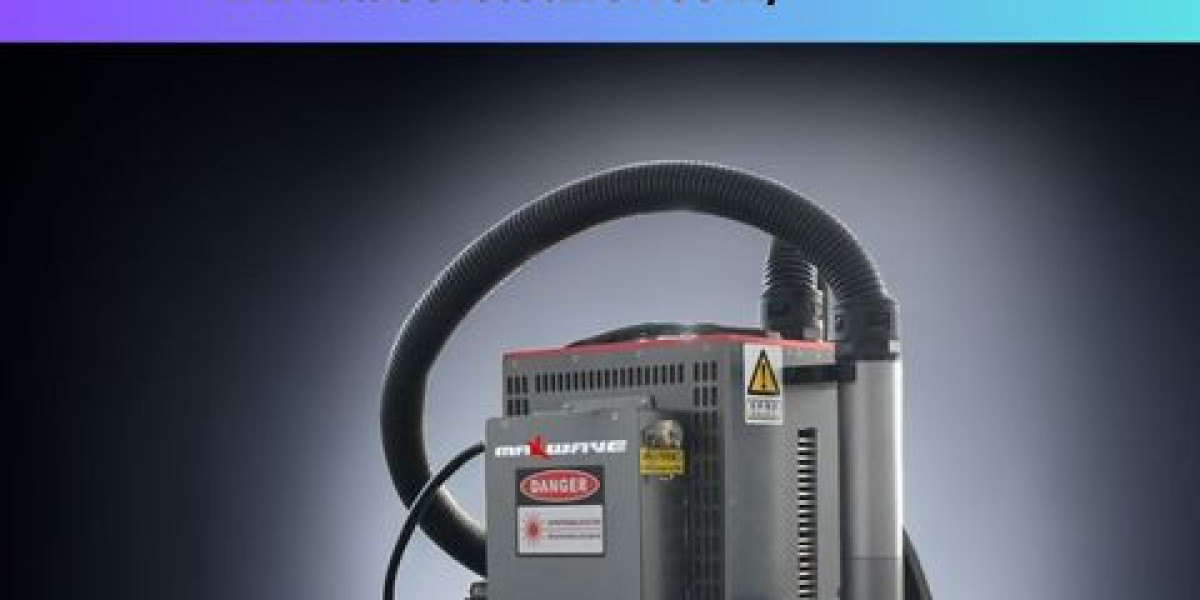

Technology Used: Pulsed fiber lasers vs. continuous wave—pulsed lasers are more expensive due to precision control.

Cooling System: Air-cooled units are cheaper; water-cooled systems are pricier but better for extended use.

Automation Level: Manual models are cost-effective; robotic or CNC-integrated units cost significantly more.

Brand & Origin: European and U.S. brands often cost more due to certifications and quality control.

Customization: Tailored solutions for specific industrial uses can elevate the price substantially.

Why Businesses Invest in Laser Cleaning Machines

Cost-efficiency and ROI are the main drivers. Although initial prices may seem high, the long-term savings and productivity gains often justify the investment.

Benefits Include:

Zero Consumables: No abrasive media or chemicals needed.

Minimal Maintenance: Fewer moving parts compared to traditional methods.

Eco-Friendly: No waste, emissions, or environmental hazard.

High Precision: Safe on sensitive surfaces like historic stone, aerospace parts, or delicate molds.

Increased Safety: No exposure to harsh chemicals or dust.

Expert Insight: How to Choose the Right Laser Cleaner

Choosing a laser cleaning machine depends on your business size, usage frequency, and material type. Here’s a quick guide:

For Light Use:

Power: 50W–100W

Budget: $3,000–$8,000

Best for: Jewelry, tools, small parts

For Regular Industrial Use:

Power: 200W–500W

Budget: $10,000–$40,000

Best for: Machinery, automotive, production lines

For Heavy-Duty Applications:

Power: 1000W+

Budget: $50,000+

Best for: Marine, aerospace, large-scale maintenance

Real-World Application Scenarios

Automotive: Removing rust and paint without damaging base metal.

Aerospace: Degreasing turbine blades with surgical precision.

Historical Restoration: Cleaning monuments without damaging stonework.

Electronics: Pre-solder cleaning on sensitive PCBs.

Frequently Asked Questions (FAQs)

Q1: How long does a laser cleaning machine last?

A: Most machines have a laser lifespan of 50,000 to 100,000 hours, depending on maintenance and usage conditions.

Q2: Can it clean painted surfaces without damage?

A: Yes, especially pulsed fiber lasers which offer precise energy control to remove coatings without harming the base layer.

Q3: Is laser cleaning better than sandblasting?

A: In most cases, yes. It’s cleaner, safer, and more accurate, especially for sensitive or intricate surfaces.

Q4: What kind of training is required?

A: Basic operation can be learned in a few hours. Advanced units may require vendor training, particularly for programming or robotic applications.

Q5: Are there government incentives for buying laser cleaning machines?

A: In some regions, yes. Especially for eco-friendly equipment, tax credits or grants may apply.

Laser Cleaning vs. Traditional Methods: Quick Comparison Table

| Feature | Laser Cleaning | Sandblasting | Chemical Cleaning |

|---|---|---|---|

| Precision | High | Medium | Low |

| Environmental Impact | Low | High | High |

| Safety | High | Medium | Low |

| Operating Cost | Low | Medium | High |

| Surface Sensitivity | Excellent | Poor | Poor |

Final Thought

As industries strive for cleaner, faster, and more sustainable processes, laser cleaning machine price stand out as a transformative investment. While the price varies significantly depending on size, power, and application, understanding the cost-benefit ratio is the key to making a smart purchase decision.